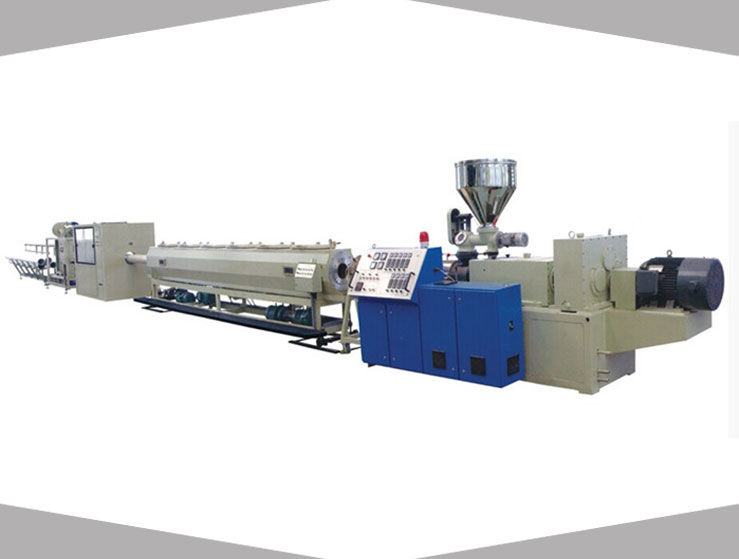

Plastic profile extruder machine

Plastic profile extruder machine

a. Plastic PVC Profile Extrusion Line

PVC profile production line is mainly used in PVC door & window profiled material, wide door plate, window plate, For different sectional surface and molds, with corresponding vacuum calibrating table, haul-off unit, cutting unit, tilter, etc. Capacity of main frame can be optionally chosen from 60-700 kgs/hour.

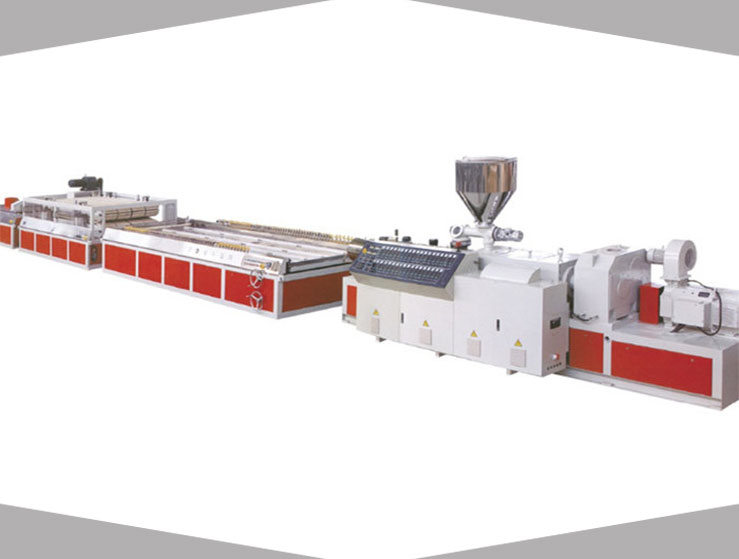

b. PVC PE PP Wood Plastic Profile Extrusion Line

This machine uses the special designed screw and barrel, die and extrusion process to produce plastic and wood products.

This production line gain the high output and stable extrusion pressure. A pre-heating feeder is mounted on the top of the extruder

c. Wood Plastic WPC Wall Panel Extrusion Line

This production line is mainly composed of conical twin-screw, mold, vacuum calibration table, traction machine, cutting machine and stacker. Production line uses automatic control, high automatic level, stable equipment, easily operate, high production efficiency. By replacing mold,

d. PVC WPC windows and doors profile extrusion production line

PVC WPC windows and doors profile extrusion line consists of a twin screw extruder, vacuum shaping table, drawing machine, plastic cutter, and pilling frame, and also coordinated with different profile break-section and mould to produce PVC doors

e. PS Foamed Picture Frame Profile Extrusion Line

PS foamed profile & plate extrusion line has compact structure, good classification, high output, long life and other advantages. This line uses a SJ65 single screw extruder or a SJ100 single screw extruder which is equipped with the inverter,

f. PVC Edge Bang Profile Extrusion Line

PVC edge band machine could produce different type edge band, with different extruder, mould and auxiliary devices.Special designed screw and bareel ensure the big output and good plasticization; Mould adopts Germany technology,