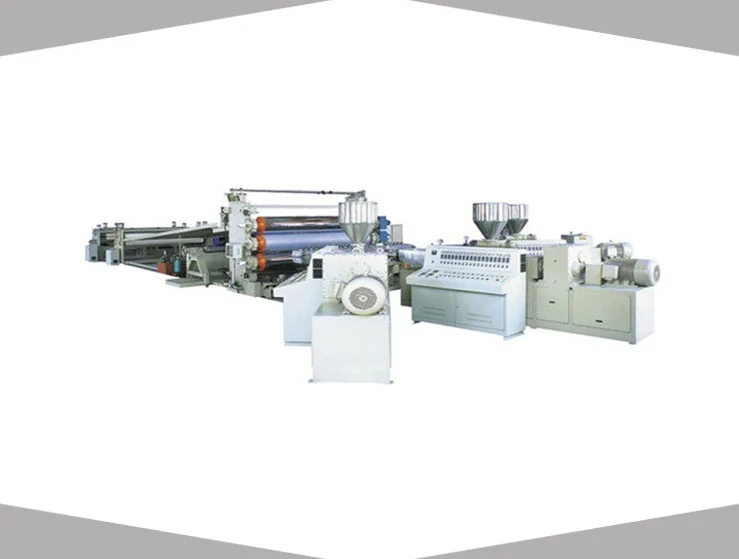

Plastic sheet and board extruder machine

Plastic sheet and board extruder machine Manufacturer

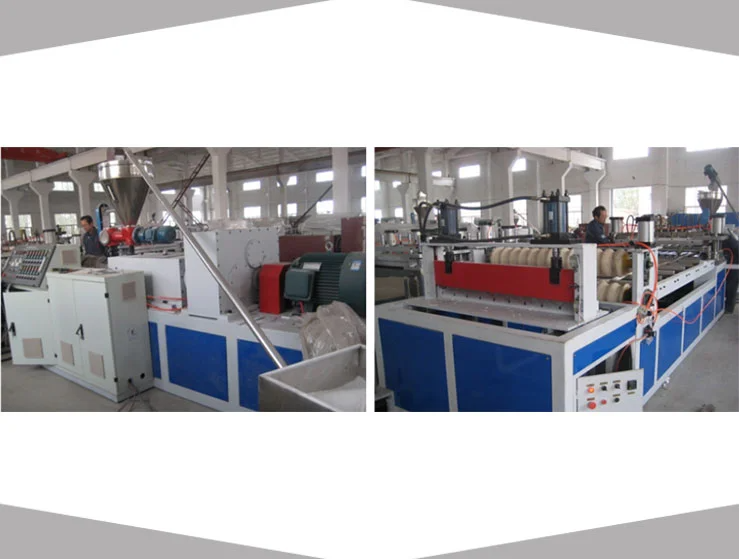

a. PVC Wood Plastic Celuka Foam Board Extrusion Line

b. PVC Wood Plastic Co-extrusion Board extrusion Line

PVC wood plastic (WPC) co-extrusion machine for skinning foam sheet use widely as

building board, cabinet board, furniture, mould for block, packaging ,recycling box,

advertisement plate, show plate, business plate, roof, ship profile, etc.

c. Plastic PVC WPC Hollow Door Panel Extrusion Line

All plastic extruder machinery components are fine tuned to work perfectly together, high quality level, latest machine design, engineered to meet the needs of customers in international markets, faster delivery times plus good service and spare parts.

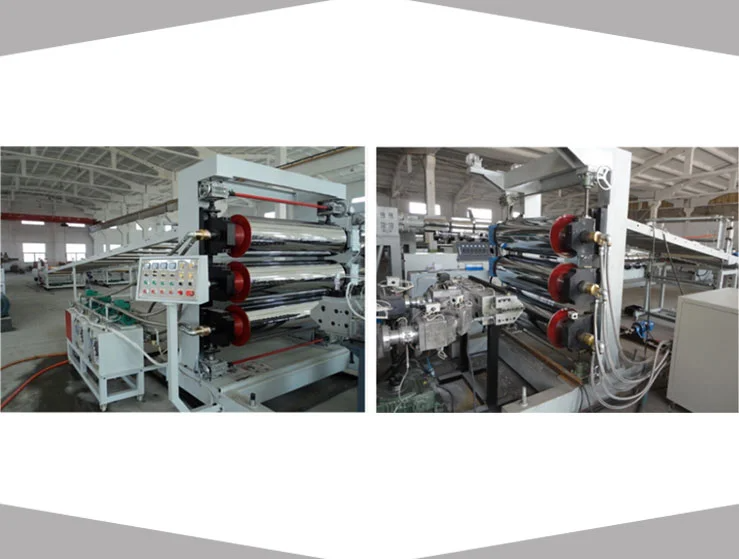

d. Plastic PC PP PE PVC Hollow Grid Board Extrusion Line

This production line realizes continuous production of PC/PP/PE/PVC hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packing.

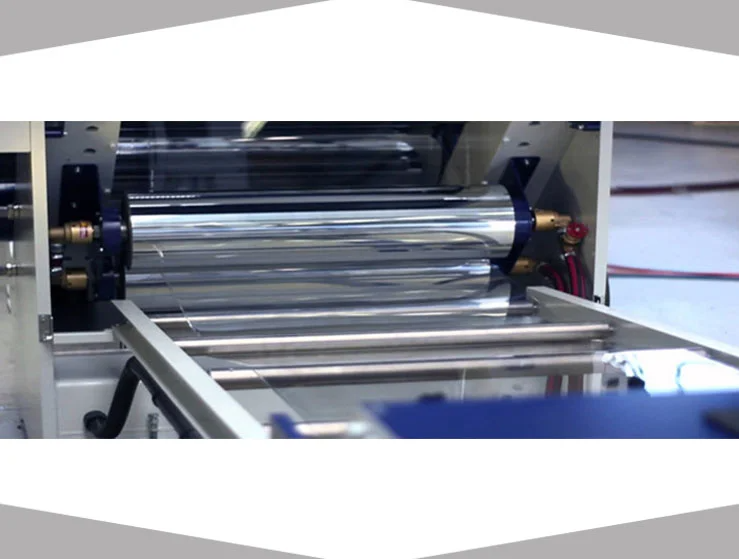

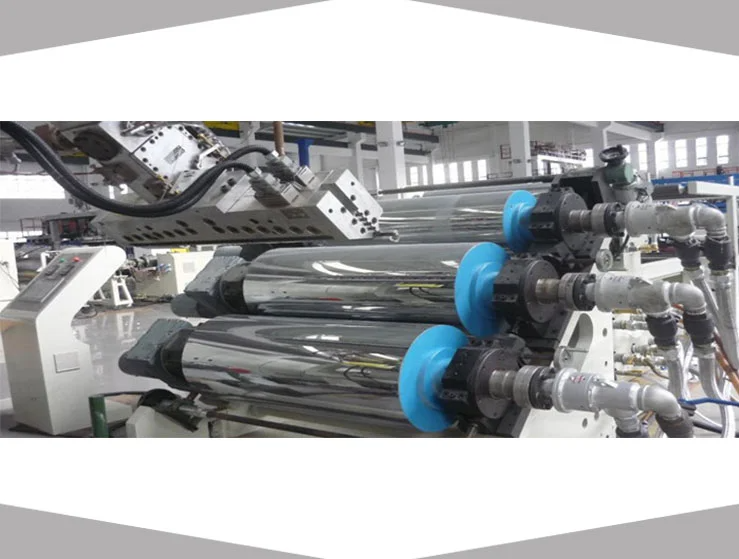

e. PE PP HIPS PET EVA Single Layer Multi-Layer Sheet Extrusion Line

f. Plastic PC PMMA PS Sheet Extrusion Line

g. ABS Single Layer Multi-Layer Composite Sheet Extrusion Line

h. Plastic PVC PP PC Corrugated Roof Sheet Extrusion Line

i. Plastic PVC Free Foam Sheet Board Decoration Sheet Extrusion Line

j. XPS Heat Insulation Foamed Plate Extrusion Line

With perfect closed alveolate construction, XPS heat insulation plate is considered to be the best insulation material in the market. Granules from recycled EPS plate, as the main material, go through the die foaming extruder, calibrator, haul-off and cutting unit. With lower density, water absorption,

k. Plastic Wide Floor Sheet, Waterproof Sheet Extrusion Line

l. Plastic PVC/PET/PP/PE/PEEK Sheet/ Board Extrusion Lin

The methods for producing plastic sheets are commonly used for calendaring, mainly for the production of sheets such as PVC and PET, and the other for extrusion, for the production of sheets such as BOPS, EPS, PET, PP, HIPS.