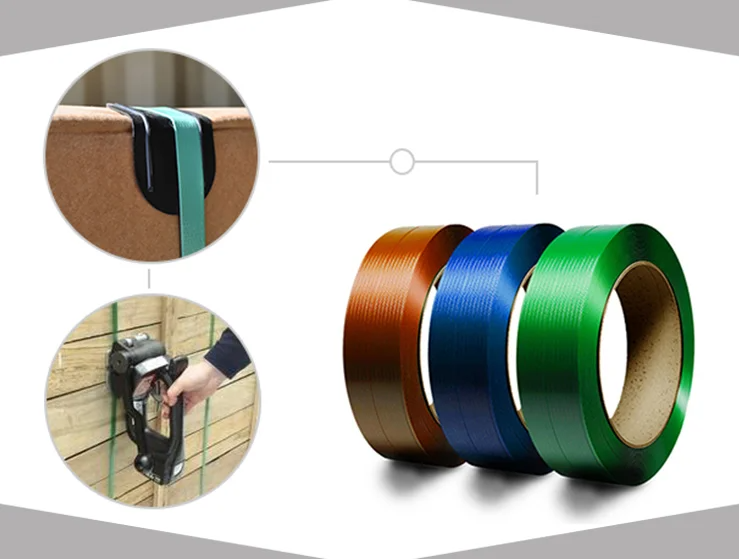

PET PP strapping band extruder machine

The PET PP strapping band extruder machine is a cutting-edge industrial equipment designed for the production of high-quality strapping bands made from polyethylene terephthalate (PET) and polypropylene (PP) materials. This advanced extruder machine employs state-of-the-art technology to melt, shape, and form these thermoplastic materials into durable and reliable strapping bands.

PET PP strapping band extruder machine

a. PET Strapping Band Extrusion Line

PET straps extrusion machine line consists of dehumidifying and crystallizing system, extruder, screen changer, mould, oven, embossing device, haul-off machine and winder etc.

b. PP Packing Belt Extrusion Line

PP strap production line is made of Hopper, Extruder, Mould, Haul-off, Oven, Printer, Embossing Machine, Cooling Tank, Winder and so on.

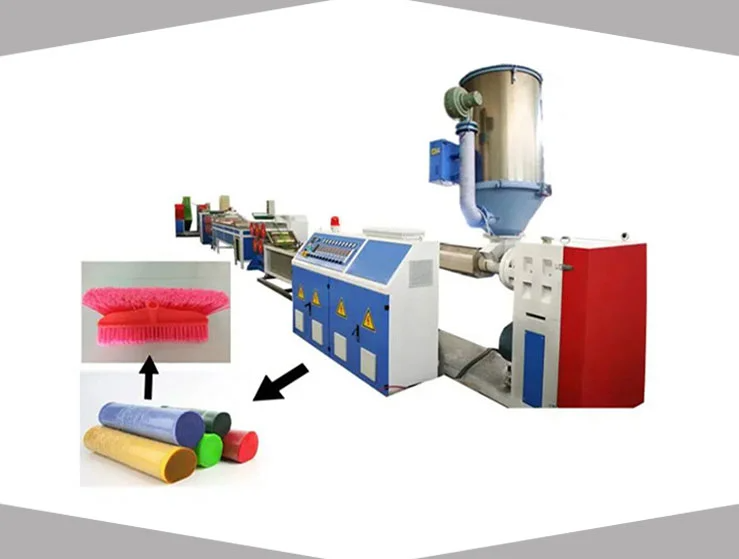

c. PET Broom Monofilament Extruder Machine

It consists of special design of PET material dehumidifying and crystallizing system, extruder, screen changer, melt pump, mold, haul-off, oven and winder etc.