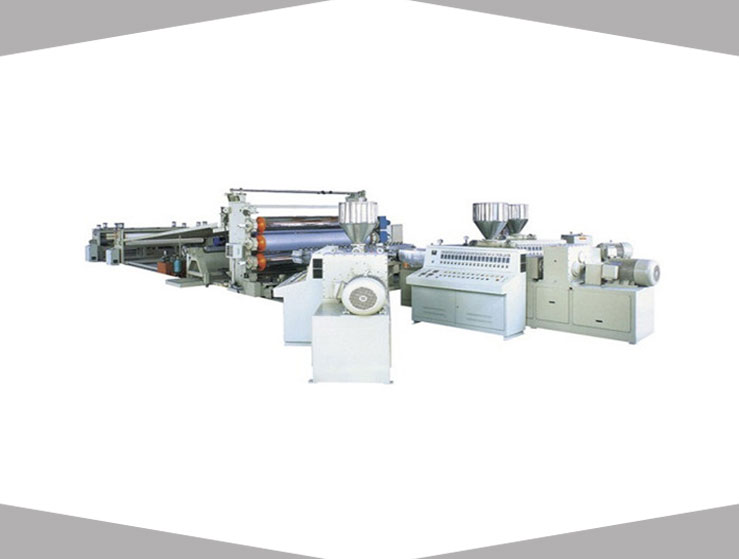

The characteristics of the machine:

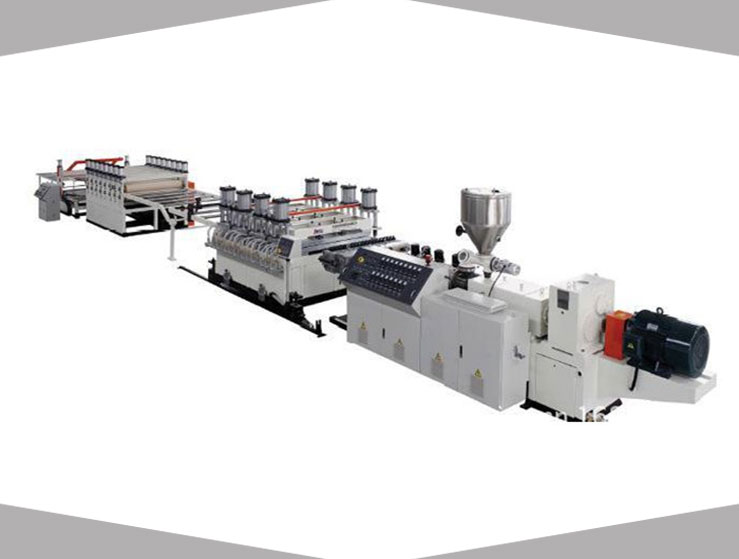

PVC wood plastic (WPC) celuka foam sheet/board machine is composed of double screw

plastic extruder, automatic vacuum feeding machine, board mould, vacuum shaping and

cutting etc. with a compact structure and superior performance. The optimum design of

the screw and the screw barrel and the adoption of the special high performance alloy

steel, make the whole machine have the advantages of uniform plasticizing, stable

extrusion quantity, high output and long service life. The barrel of the extruder is heated

by the cast aluminum heater and cooled by the wind flow to keep the temperature under

control which is measured by the precision electric meter. The board can be well shaped

through the precise calibration forming machine which can be adjusted flexibly. As for the

automatic cutting part, the fixed length cutting device is adopted to guarantee the precise

length of the board. The brands of the electrical component applied in the equipment are:

SIEMENS, ABB, SCHNEIDER and other international brands (non counterfeit).

Application:

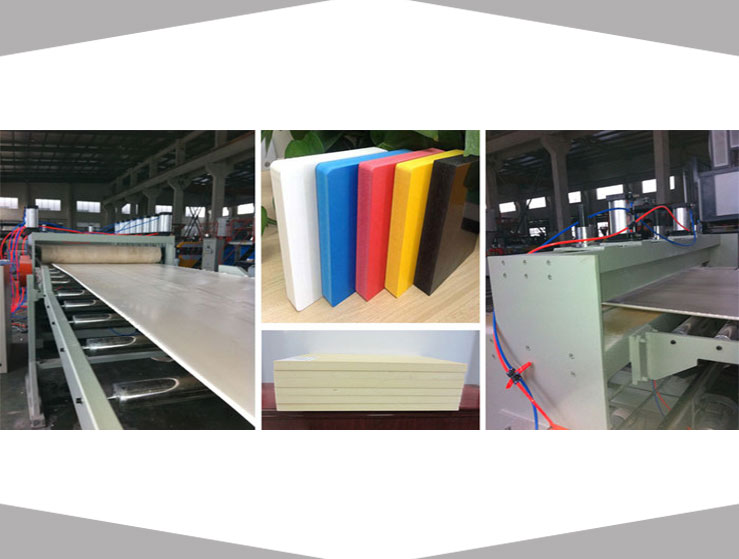

1.Household decoration: Building templates, bathroom cabinet board, kitchen cabinet,

furniture board, home decoration board, various household shelves.

2. Advertisement industry:Screen printing, computer engraving, advertising board,

exhibition plate, logo plate.

3. Architecture decoration industry: building template board, outdoors plate, indoors

decoration plate, residential house, office, separation of public building, commercial

decoration frame, plate used in dust-free room, celling plate.

The Prospect of PVC WPC Furniture Board:

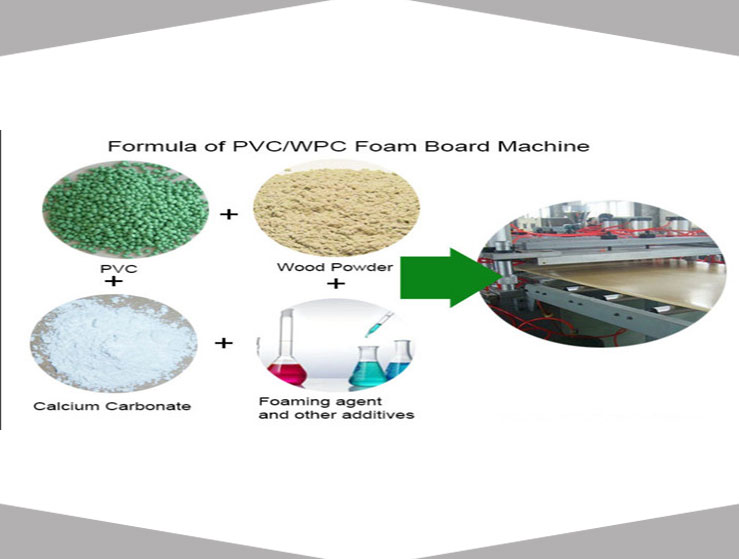

Nowdays WPC (wood plastic composite) industry has developed rapidly all over the world

with a great prospect. The potential of the WPC and its benefits on ecological environment

are recognized by many countries. Given to its excellent and unique performance, WPC

has proved itself that its application and significance can’t be replaced by other product. It

does play an important role in the society development and the environmental protection.

It is the inevitable trend of the human society civilization progress.

Quality warranty:

1, We provide a one-year warranty on all products.

2, After sale service and parts interchange during warranty period free of charge.

3, Life time paid warranty available.

Your benefits with our machines:

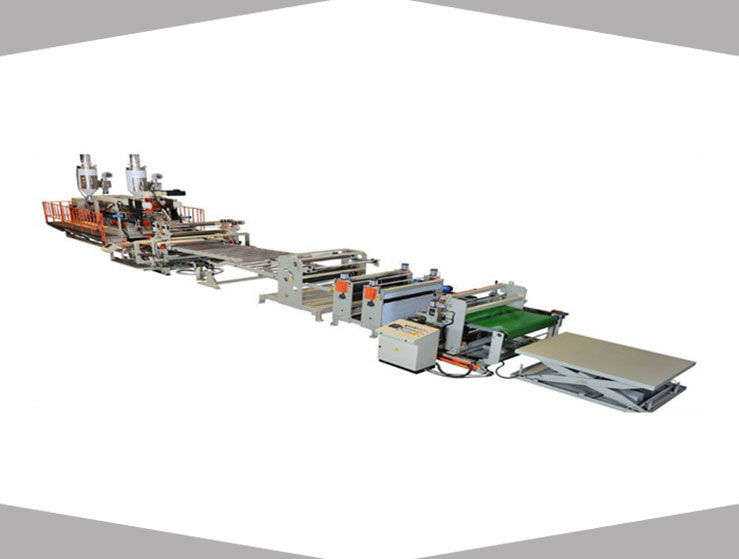

All plastic extruder machinery components are fine tuned to work perfectly together, high

quality level, latest machine design, engineered to meet the needs of customers in

international markets, faster delivery times plus good service and spare parts.

Reviews

There are no reviews yet.