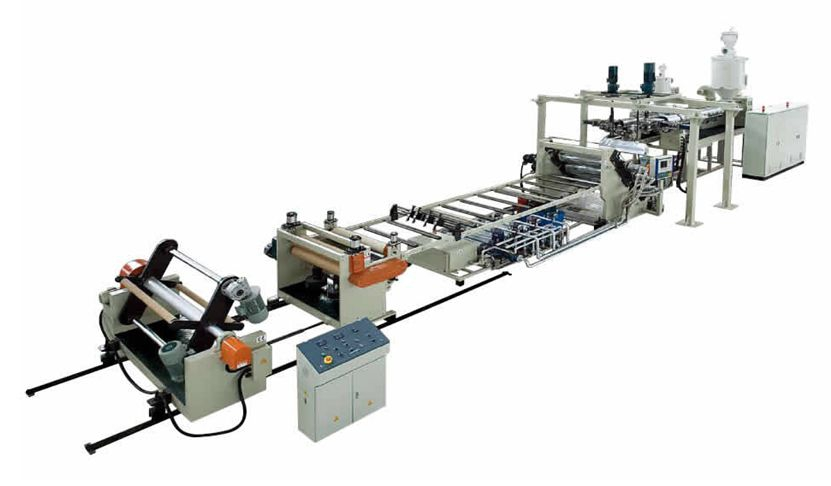

Plastic PC PMMA PS Sheet Extrusion Line -is used for the production of Plastic PC PMMA PS sheets. The thickness of their working range is 0.6 – 15 mm and the width is under 2500 mm.

For making car windows to smartphones, these sheets are used nowadays. Plastic PC PMMA PS sheets are a good alternative to glass. You will get more resilient compared to glasses.

More strength and less price – these two features make Plastic PC PMMA PS Sheet more popular. And to take your first step in this industry you need to have an extrusion line to cut the sheet into your desired form.

If you are curious to know more details, this article is the right place for you. Here we will talk about the features of this machine in detail. So, let’s take a look!

Uses of Plastic PC PMMA PS Sheet Extrusion Line?

The Plastic PC PMMA PS Sheet Extrusion Line is specially manufactured for extruding Plastic PC PMMA PS sheets. When you are about to enter into vast production of this material, you must set up this machine. It offers a smooth, clean output in each cutting.

PC PMMA PS sheets are mostly used in the construction industry. This material is hard, rigid, and highly scratch resistant. As a result, they are used in making bulletproof glasses, safety glasses, pool covers, aquariums, etc.

What You Need to Check Before Buying The Plastic PC PMMA PS Sheet Extrusion Line

There are some factors that you need to look into before buying your Plastic PC PMMA PS Sheet Extrusion Line. The below points will tell you the details of it.

Core Part of The Machine

Machine configuration is the first thing that you need to have a clear idea of before taking your buying step. Without knowing it, you might end up with a loss of investment.

That’s why you must know the core feature of a Plastic PC PMMA PS Sheet Extrusion Line, to get the basics of this machine. The extrusion line comes with the following core parts –

- Screw

- Temperature control

- Three-roller calendar

- Slicing machine

- Winder with torque motor

- Metering machine

Be sure about the quality and their working capacity before making your buying decision.

Mechanism System

A good extrusion line features an automated system. They let you adjust the width, length, and thickness of your cutting. So, you can get perfect sheets as per your requirements.

After-Sale Service

You must ensure the durability and quality of your product before purchasing, one way to do that is to check the warranty and after-sale service offer. A good quality machine comes with at at-least a one-year warranty on all parts. A company also provides a free replacement guarantee when they are confident about their product.

Think about SANA – TORY TECH which is located in Shandong Province, China. This extrusion line manufacturer company offers its customers a one-year warranty as well as a lifetime paid warranty. You can also change any parts of the machines free of charge during the warranty period.

When a company like SANA – TORY TECH gives such offers it means they are very sure about their product. As a result, you can rest assured that your PC PMMA PS Sheet Extrusion Line is fully functional and will remain productive for a long period.

Final Words

Now you know about the Plastic PC PMMA PS Sheet Extrusion Line. While you are up to buying a plastic extruder machine, be sure all the components are fine-tuned and are able to meet your requirements. With a one-time purchase, you can get years of service if the quality is good.

Know more about: About PE PP HIPS PET EVA Single Layer Multi-Layer Sheet Extrusion Line