With the plastic extruding process, people now produce various items such as plastic sheets/boards, tubes/pipes, plastic films, window frames, deck railings, etc. From underground construction to aerospace, plastic extruding products are vastly used in recent years. Plastic pipe-extruding machines take materials into alignment guides and shaped them into pipes.

To build a better business company, there is no more reasonable tooling process than plastic extruding machines. You can produce more products employing very less plastic materials. Also, there are other several benefits you can get from this process. So, buying an extruding machine is a clever idea for the growth of your business. In this discussion, we will describe the introduction of a single-wall plastic corrugated pipe extruder machine and how to select a better extruding machine.

What is a single-wall plastic corrugated pipe extruder machine?

The single-wall corrugated pipe is best for drainage projects because it’s lightweight and inexpensive. It has a corrugated design which gives it more flexibility. That’s why it is easy–to–imply. It’s a solution to common residential stormwater drainage problems. The single-wall corrugated pipe machine is used to produce corrugated pipes.

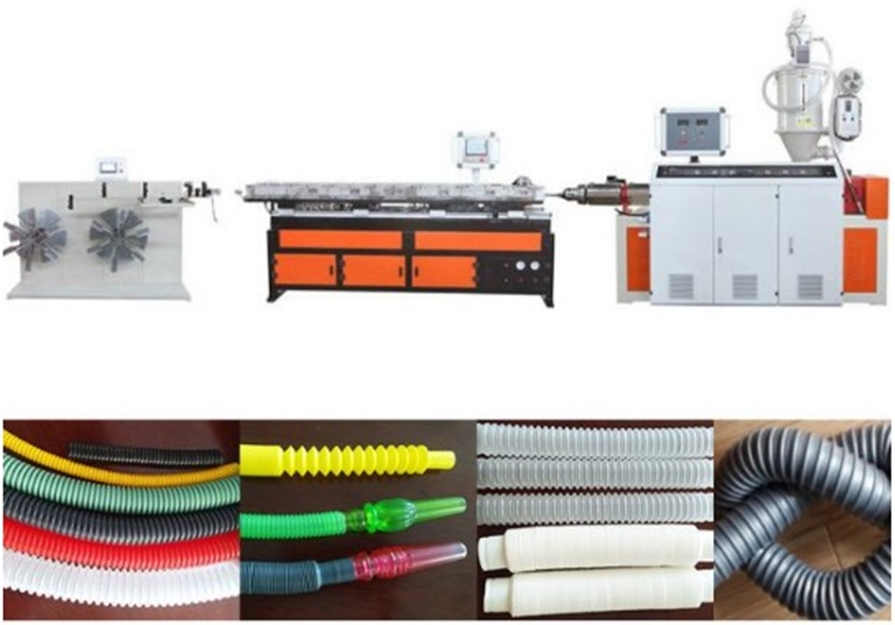

It is mainly formed of an extruder die-head, corrugated pipe forming machine, forming machine chain mould, and winding machine. It has a single screw mould-forming winder to make produce pipes in a continuous manner. In the process of making pipes, it automatically shrinks and cuts the pipe into the required shapes. These extruder machines have high production speed, high continuity, and easy operation and can promote production efficiency and save labor costs.

Some beneficial features of single-wall plastic corrugated pipe extruder machine

- It has features of high-temperature resistance.

- This machine is resistant to corrosion and abrasion.

- It provides high intensity.

- Flexibility is the most crucial feature of a corrugated pipe extruder.

- Two sizes in one mould for small pipes can reduce mold costs.

- Reduce the frequency of replacement of mold.

- Effectively improve production efficiency.

- It has a smooth complete outlook.

- It works in full digital control.

- It provides various types of shapes for making different usages.

- It has a single screw design which equips a high speed of production.

- A corrugated pipe extruder can offer you excellent performance with low energy consumption.

Before buying a corrugated pipe extruder, check that these features are available.

How will you pick a suitable extruder for your company?

There are a bunch of extruders is available in the market. But to find a better extruder, you have to follow some instructions. It will help you to choose an extruder that can provide you with the best products at a low cost.

Analyze the brands and price

Before buying an extruder, you have to analyze the worldwide brands with their offering prices. There are several countries that import extruding machines with a range of prices. Compare the brands from those countries and pick a brand that offers low prices. After analyzing the countries, brands, and prices, you will understand which brand can give you the best quality machine in your budget. For example, China has some best extruder brands.

Analyze the standard technology of plastic extrusion machines

A plastic extruding machine has some major technology including an extruder, a mould, a die, a cooling tank, and a haul-off. Before selecting an extruder, you must ensure that all the devices are fine and smooth.

Conclusion

Furthermore, you can also analyze the features of the machine. You will notice that in china some brands offer a lot of features in their machines at a reasonable price. And also single-wall plastic corrugated pipe extruder is less costly than others. So, it’s a profitable thought to buy a corrugated pipe extruder machine.

Know more about: Why does the water well PVC pipe-making machine is cheaper?