Introduction to PVC Wood Plastic Composite

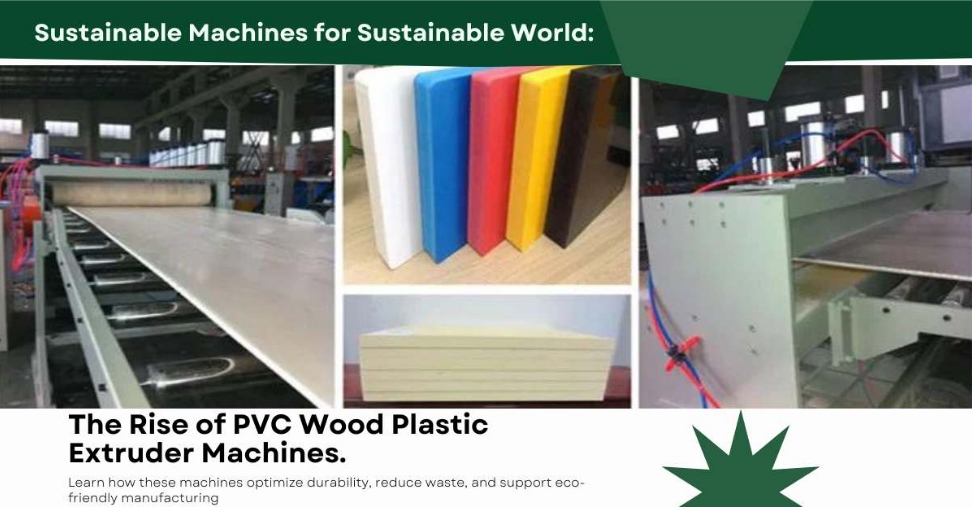

In the realm of construction and manufacturing, innovation drives sustainability and efficiency. Among these innovations, the PVC Wood Plastic Composite (WPC) stands out for its remarkable properties. Combining the resilience of plastic with the aesthetic and ecological benefits of wood, this material has revolutionized various industries, particularly construction and outdoor furnishings.

Understanding the Extrusion Process

The heart of WPC production lies in the extrusion process, a method that melds raw materials into a continuous, versatile form. This process is not just about shaping; it’s about engineering materials to enhance their inherent properties, making them more durable, weather-resistant, and versatile for various applications.

Key Components of the Extruder Machine

Central to the machine’s efficiency is its screw design, which determines the material’s mixing, heating, and propelling through the die. Additionally, the heating and cooling systems play a pivotal role in ensuring the material’s properties are perfectly aligned with the desired outcome.

Types of PVC Wood Plastic Sheet and Board Machines

Diving deeper, we explore the distinctions between single and twin-screw extruders and the specialized realm of co-extrusion machines. Each type offers unique benefits, tailored to different production needs and material characteristics.

The Production Process Step-by-Step

From material preparation to the final finishing touches, each step in the production process is critical. This section walks through the journey of raw materials transforming into high-quality WPC products, highlighting the meticulous attention to detail required at each stage.

Quality Control in Extrusion

Quality control is not just a step but a continual process integral to manufacturing. We discuss the key parameters monitored and the practices ensuring every sheet and board meets the highest standards.

Applications of PVC Wood Plastic Composites

WPC’s versatility is showcased in its wide range of applications, from robust construction materials to elegant outdoor furniture and decking. This section explores the material’s impact on different industries and its role in shaping modern architecture and design.

Innovations in Extrusion Technology

The extrusion field is ever-evolving, with technological advancements promising even greater efficiencies and capabilities. Here, we delve into the latest innovations and the exciting future trends that are set to redefine the industry.

Cost Analysis of Extruding PVC Wood Plastic

Understanding the financial aspects, including the initial investment and operational costs, is crucial for businesses considering entering the WPC market. This analysis provides valuable insights into the economic considerations of WPC production.

Maintenance and Troubleshooting

Like any sophisticated machinery, extruder machines require regular maintenance and occasional troubleshooting. This section offers tips and solutions for common issues, ensuring longevity and consistent performance.

Environmental Impact and Sustainability

In today’s eco-conscious world, the environmental impact of production processes is a significant concern. We examine the sustainability of WPC, focusing on its eco-friendly aspects and the industry’s efforts in recycling and waste management.

Choosing the Right Extruder Machine

The final piece of the puzzle is selecting the appropriate extruder machine. Factors to consider and recommendations for prospective buyers are provided, ensuring an informed decision-making process.

PVC Wood Plastic Sheet and Board Extruder Machine FAQ

1. How does the extrusion process benefit PVC Wood Plastic production?

The extrusion process allows for efficient, consistent blending of wood fibers and plastic, producing durable, versatile WPC products with the benefits of both materials.

2. What makes twin-screw extruders preferable for certain WPC applications?

Twin-screw extruders offer superior mixing, handling a wider range of materials and producing WPCs with consistent quality and structural integrity.

3. Can WPC products be recycled, and if so, how?

Yes, WPC products can be recycled by grinding them into particles and reusing those to make new WPC products, supporting sustainability.

4. What are the key maintenance routines for an extruder machine?

Key routines include cleaning the screw and barrel, replacing worn parts, lubricating moving components, and following the manufacturer’s maintenance schedule.

5. How do environmental regulations impact WPC production?

Regulations set standards for emissions, waste management, and use of recycled materials, ensuring WPC production is environmentally responsible.

6. What should buyers look for when choosing an extruder machine?

Buyers should consider the machine’s capacity, versatility, energy efficiency, maintenance ease, technical support, and total cost of ownership to ensure it meets their production needs and offers the best value.

Conclusion

We wrap up with a summary of the transformative potential of PVC Wood Plastic sheet and board extruder machines, emphasizing their role in promoting sustainability, efficiency, and innovation in the construction and manufacturing sectors.