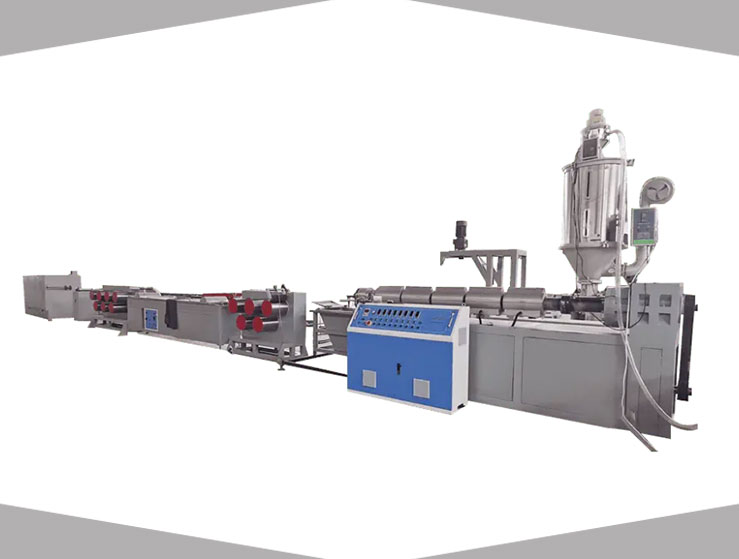

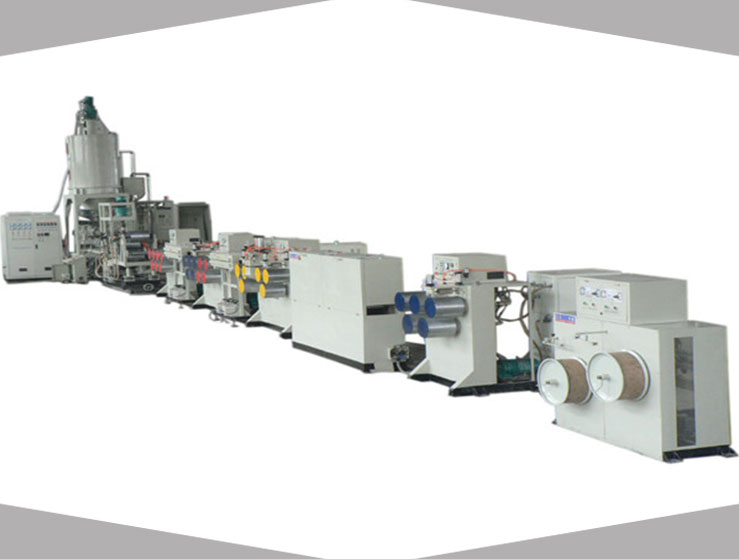

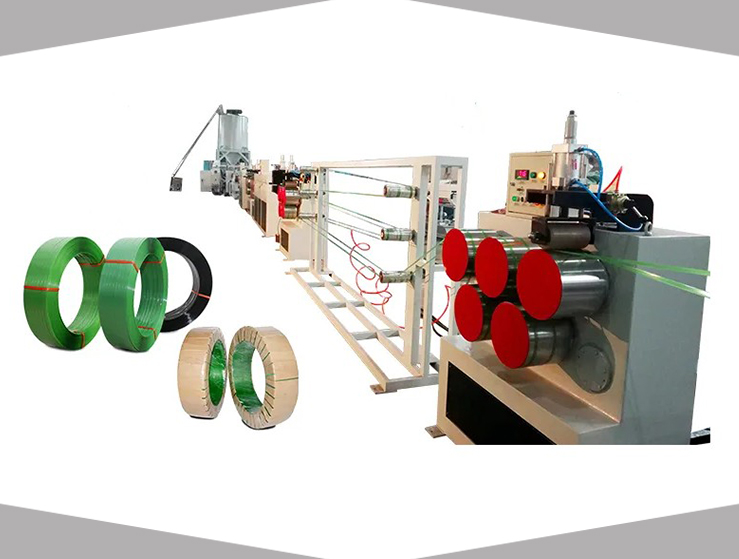

Components:

It consists of special design of PET material dehumidifying and crystallizing system, extruder, screen changer, melt pump, mold, haul-off, oven and winder etc.

Production process:

Material—dehumidifying and crystiallizing—Extruding—Filter—Metering—Mold—

Cooling—Haul-off—Oven heating—Haul-off—Glazing—Shaping—Haul-off—Winding

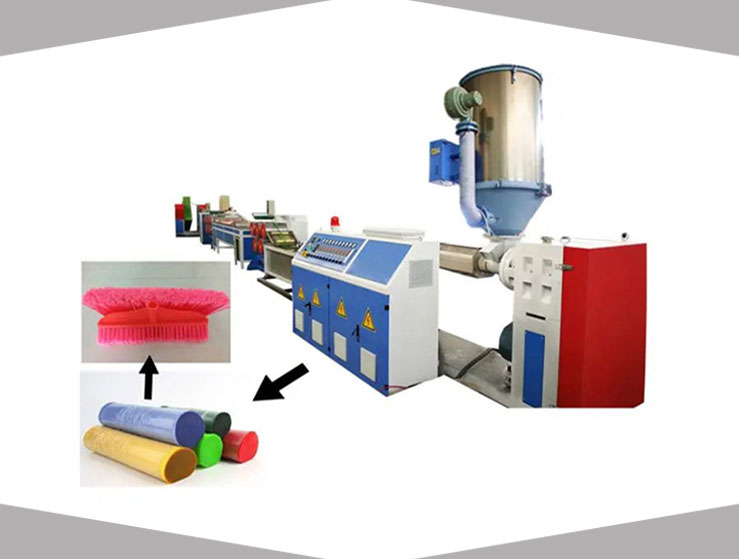

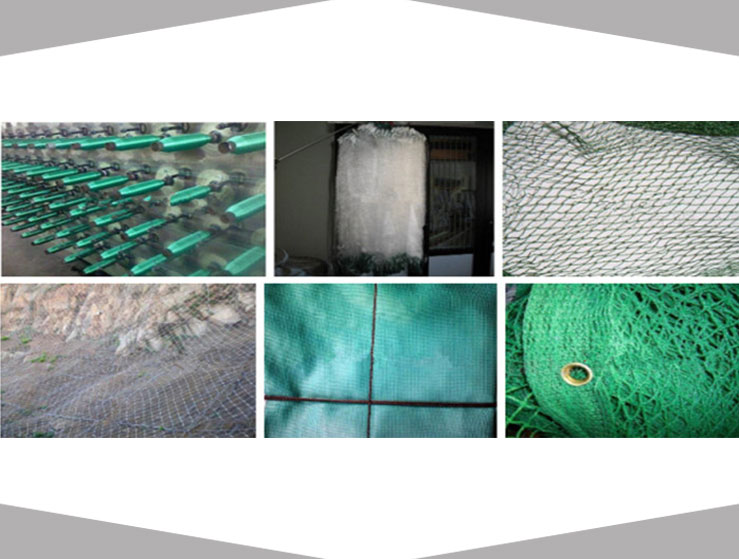

Application:

With 100% bottle fakes recycled material, to produce PET monofilament, like broom filament, zipper filament, Christmas tree filament, fishing net wire, construction fence etc.

Features:

- With 100% bottle fakes material, or mixed with PET raw material.

- New technology, hot wind cycles to dry, increase the viscosity of the bottle fakes material, secondary stretching, increase the tensile strength and elasticity.

- Precise and energy saving temperature control system, power saving, low noise, low imput and high yield.

- Single screw extruder, compared with low degradation of twin screw extruder.

- Easy operation, convenient maintenance, the labor and the electricity cost is low.

Quality warranty:

1, We provide a one-year warranty on all products.

2, After sale service and parts interchange during warranty period free of charge.

3, Life time paid warranty available.

Your benefits with our machines:

All plastic extruder machinery components are fine tuned to work perfectly together, high quality level, latest machine design, engineered to meet the needs of customers in international markets, faster delivery times plus good service and spare parts.

Reviews

There are no reviews yet.