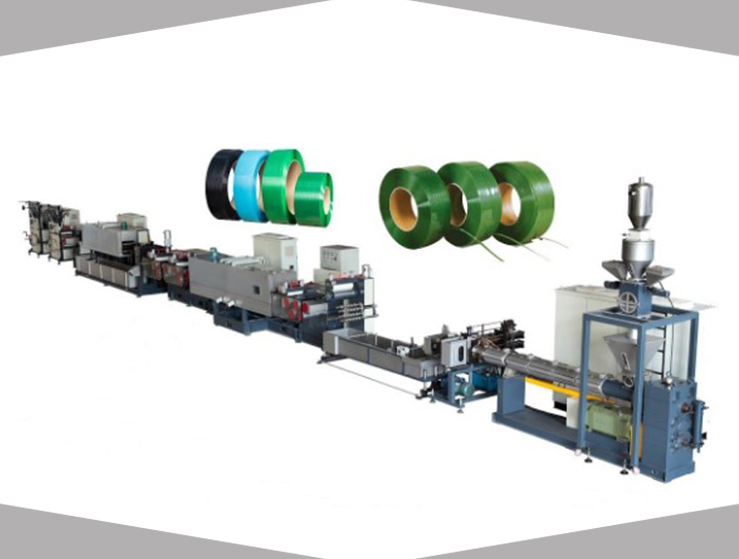

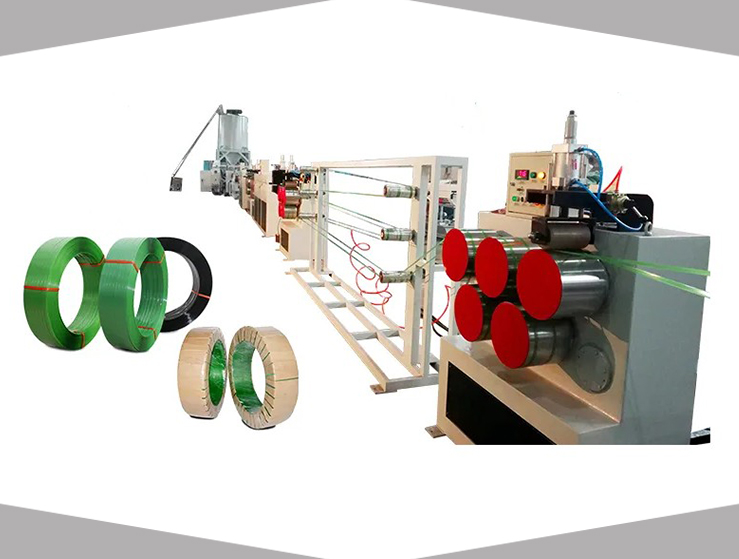

Characteristics of our PET packing strip extruder machinery:

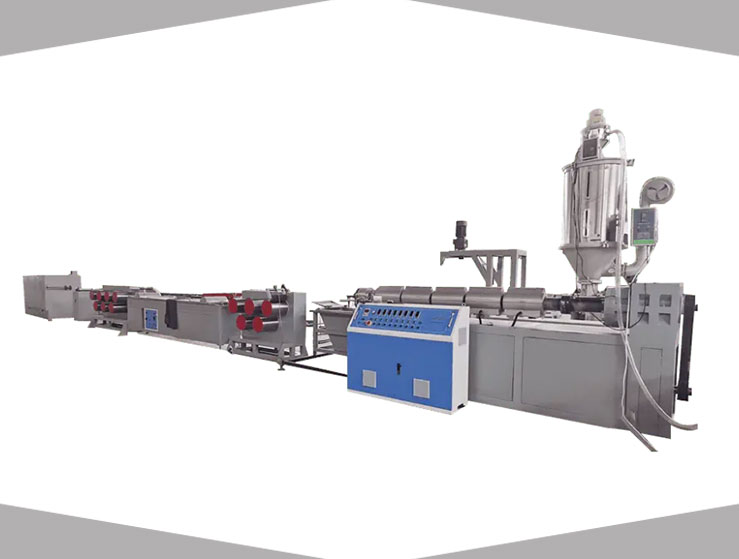

1. The raw material treatment is by our CSG serious dehumidifier and dryness system, it ensures the humidity in raw material less than 80PPM.

2. Closed circulation feeding system prevent the material from exposure to air to keep the dryness of raw material.

3. The screw is specially designed for PET application, it consists of separate and mixing parts to keep the even plastination, also by a fixed material feeding system, the extrusion is stable, which ensures the good dimension of the PET strap.

4. The machine can produce a 1/2/4 strap at the same time.

5. The mold is specially designed, and equipped with a two-stage filter.

6. Constant temperature heating device provides an even cooling environment for PET straps to raise the tensile strength performance.

7. Anneal treatment for finished PET strap to remove the part remaining stress to keep a good shape

8. The winder is double disk type with easy operation and coil changing.

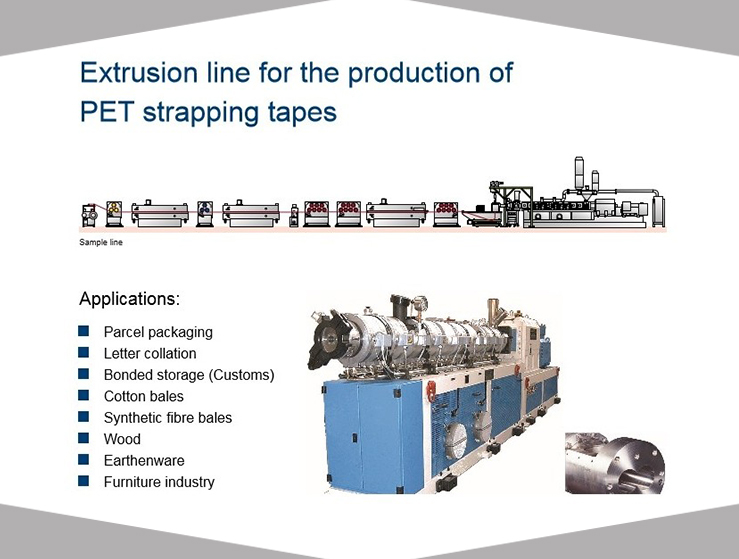

PET packing strip application:

PET packing strap is widely used, and replaced by steel strap for packing application internationally, because of their good tensile strength, flexibility, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

We provide solutions of the whole line as well as all your technology request.

Main technical parameters:

| No | Line spec | Capacity(kg/h) | Strap size (mm) | Power consumption | Cooling Type |

| 1 | 65 single line | 50-100 | 9-20 | 40-50kw | Water tank |

| 2 | 65 double line | 100-150 | 9,11,13,16 | 40-50kw | Water tank |

| 3 | 75 single line | 150-200 | 9-25 | 55-60kw | Water tank |

| 4 | 75 double line | 200-250 | 11,13,16,19 | 55-60kw | Water tank |

| 5 | 90 double line | 250-300 | 9,12.7,16,19 | 70-90kw | Water tank |

| 6 | 120 four strap line or 75 parallel screw line |

250 | 32,25,19(double) 16,12.7,9(four) |

150-170kw | Water tank |

Quality warranty:

1, We provide a one-year warranty on all products.

2, After-sale service and parts interchange during the warranty period free of charge.

3, Lifetime paid warranty available.

Your benefits with our machines:

All plastic extruder machinery components are fine-tuned to work perfectly together, high quality level, latest machine design, engineered to meet the needs of customers in international markets, faster delivery times plus good service and spare parts.

Reviews

There are no reviews yet.