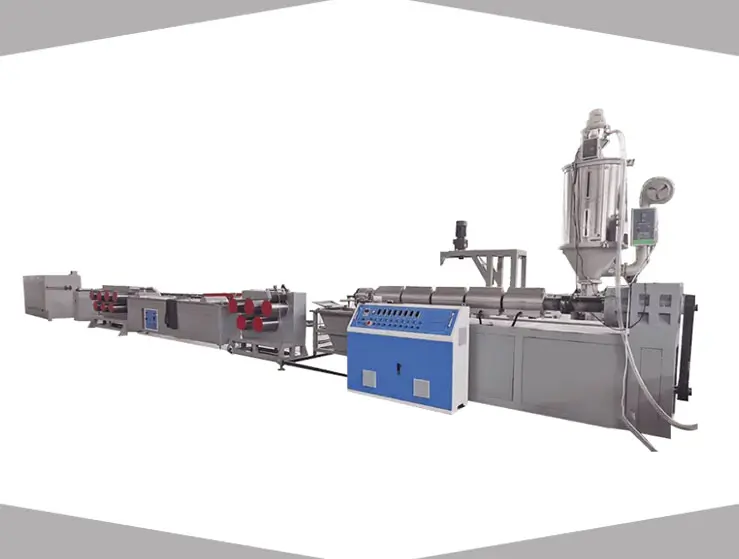

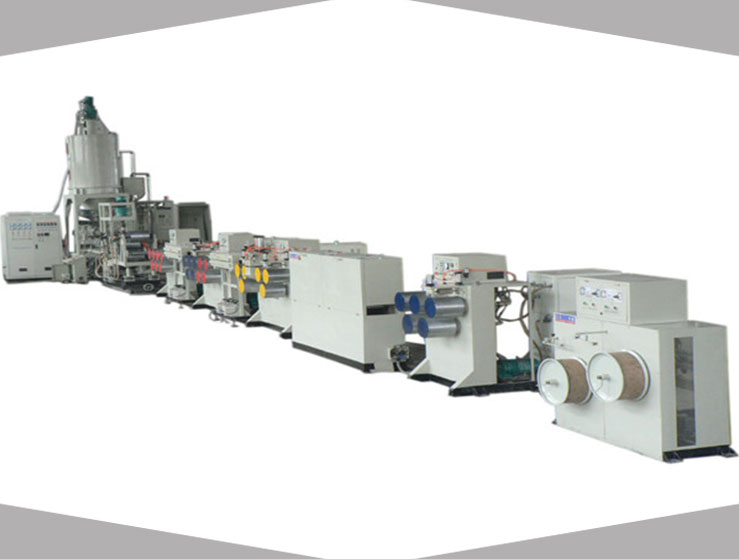

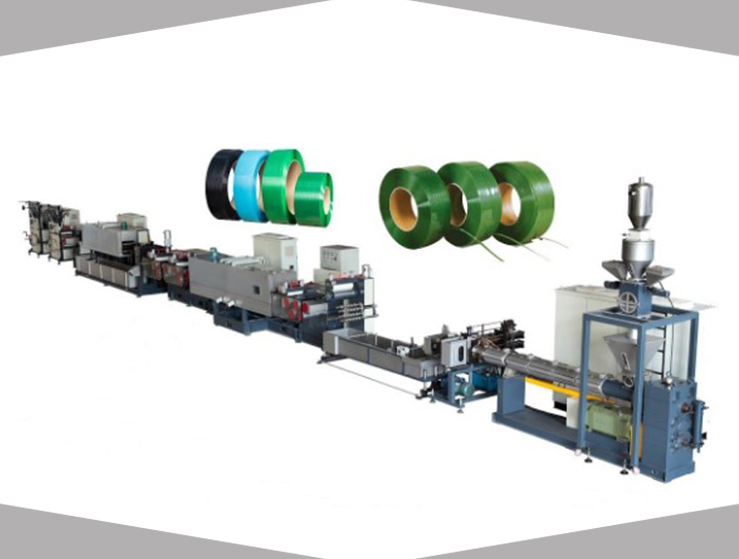

Components of PP strap extruder machine

PP strap production line is made of Hopper, Extruder, Mould, Haul-off, Oven, Printer, Embossing Machine, Cooling Tank, Winder and so on.

Technology process

Drying—Extruding—Cooling—Dewater—Drawing—Heating—Drawing—Printing—

Shaping—Cooling—Dewater—Drawing—Winding

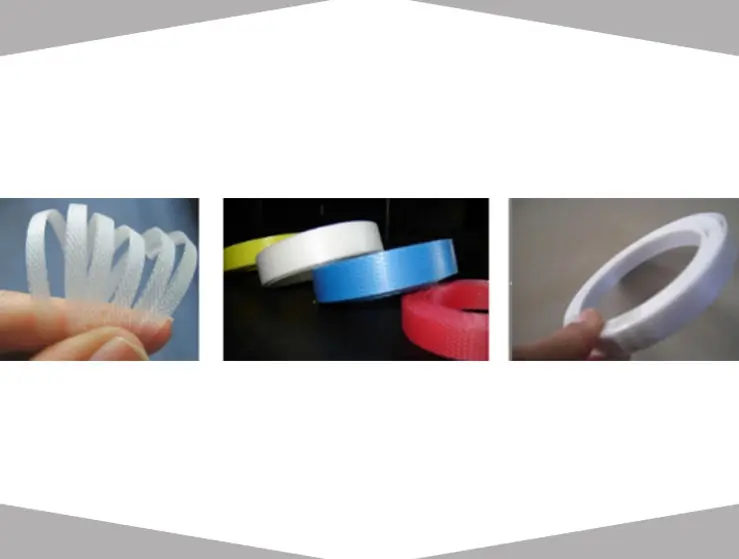

Application of PP strap

Used to pack cartons, canned food, compressible products, board, aluminum, ingots etc.

Features of PP strap machine:

- Apply to raw material and recycled materials, it can produce both environmental protection advanced strap and recycled strap.

- The products with high tensile strength, no split, no crack, high market recognition.

- Good shape, even size, achieve automatic packing level.

- Automatic constant temperature control device.

- Advanced technology, make the product cost is lower more 10% than the same industry.

- Low noise, less consumption, high efficiency, long service life.

Quality warranty:

1, We provide a one-year warranty on all products.

2, After sale service and parts interchange during warranty period free of charge.

3, Life time paid warranty available.

Your benefits with our machines:

All plastic extruder machinery components are fine tuned to work perfectly together, high quality level, latest machine design, engineered to meet the needs of customers in international markets, faster delivery times plus good service and spare parts.

Reviews

There are no reviews yet.