Brief introduction:

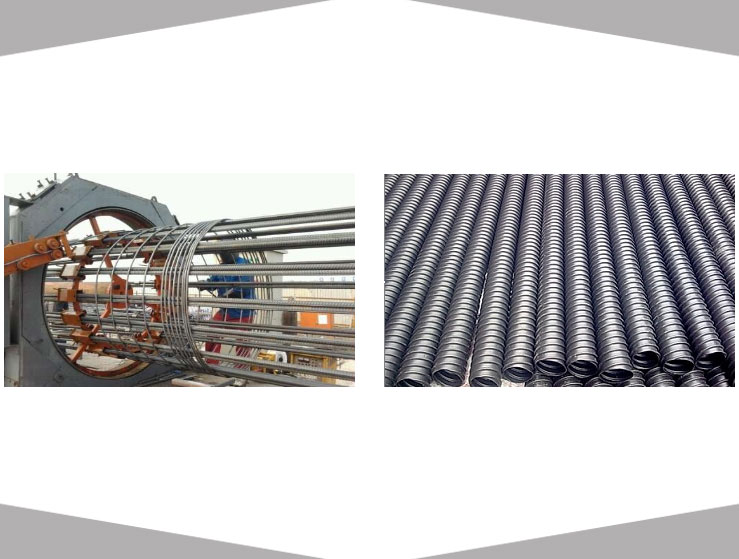

The raw material of the plastic corrugation pipe is HDPE, resisting corrosive, acid and alkali, preventing the prestressing muscle from boing eroded. Many prestressing structure snuffer severe influence from environment, such as deice salt or brine. Metal pipe have not permanent anticorrosive capability, cannot rosiest water leakages, while plastic corrugation is capable to provide a barrier protection for prestressing muscle, prevent the insurant pollution from penetrating the pipe, therefore, good pordurable performance of prestressing structure is guaranteed.

At the same condition, the friction coefficient of preset hole for plastic corrugation pipe are distinctly smaller than that of metal pipe, reducing friction loss of prestressing in the course of tension. Generally, friction coefficient of the plastic pipe is 0.14, while for metal pipe it is 0.25, the plastic pipe having high strength, bearing jam on and it’s airproof performance and leakage resistance is superior to that of metal pipe, more suitable to vacuum grouting.

Quality warranty:

1, We provide a one-year warranty on all products.

2, After sale service and parts interchange during warranty period free of charge.

3, Life time paid warranty available.

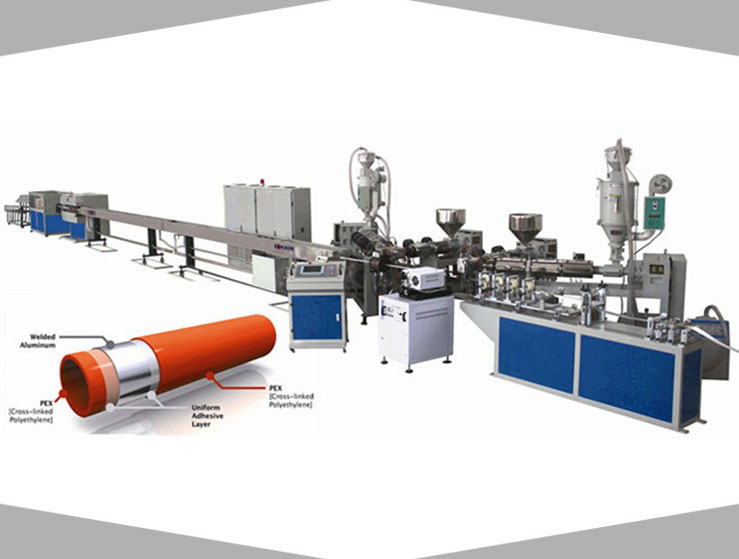

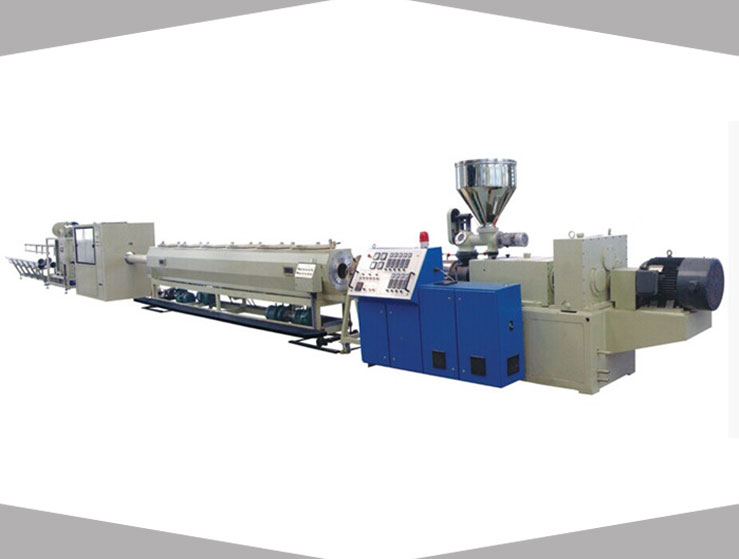

Your benefits with our machines:

All plastic extruder machinery components are fine tuned to work perfectly together, high quality level, latest machine design, engineered to meet the needs of customers in international markets, faster delivery times plus good service and spare parts.

Reviews

There are no reviews yet.