Machine info:

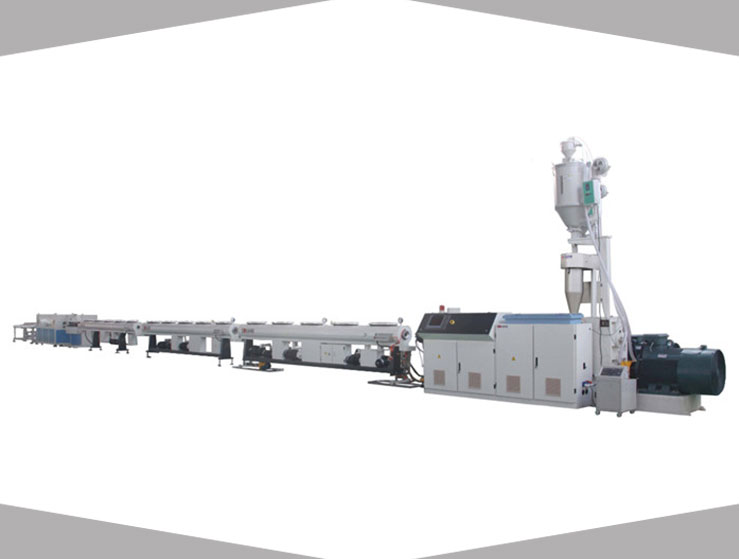

The whole HDPE/PP double wall corrugated pipe production line is suitable for the high speed extrusion of HDPE, LDPE, and PP material.

It adopts high speed high efficiency single screw extruders directly extruding forming technology, special structure die head, forming stably. Corrugator adopts horizontal structure with chain type transmission. Aluminum alloy mold blocks equipped with open water cooling system and advanced self-lubrication system to improve production speed greatly. The whole production line adopts Germany Siemens professional PLC control system, high automation, reliable running, and easy operation.

PE double wall corrugated pipe production line adopts complicated mechanic head ,double combated machine to production to provide material and spiral writhe .

For HDPE, you can choose high efficient single screw extruder.

For PVC, you can choose conical twin screw extruder or parallel twin downstream equipment

The forming system of this line consists of mould and corrugator. The mould blocks can be easily changed and they may have air or water cooling system.

High precision and character for forming machine and head die.

Water and wind cooling for module

On-line belling

Unique digital control system

High automatic, high output, stable production condition.

Main technical parameters:

| Single Wall Corrugated Pipe Production Line | |||

| Extruder | SJ-65/25 | SJ-90/25 | SJ-120/25 |

| Range of Pipe Dia. | 16-50 (mm) | 65-115 (mm) | 115-175 (mm) |

| Water Consumption | 2000 (L/H) | 4000 (L/H) | 5000 (L/H) |

| Water Pressure | 0.4-0.6 (Mpa) | 0.4-0.6 (Mpa) | 0.4-0.6 (Mpa) |

| Number of Mold Blocks | 40 (Pairs) | 50 (Pairs) | 60 (Pairs) |

| Total Length of Mold Blocks | 2400 (mm) | 5180 (mm) | 6216 (mm) |

| Speed of Mold Blocks | 1-8 (m/min) | 1-12 (m/min) | 1-8 (m/min) |

| Dimensions(LxWxH)(Approx) | 10×1.25×1.5(M) | 18×1.35×1.7(M) | 21×1.55×2.2(M) |

| Total Weight (Approx) | 3 (Ton) | 6 (Ton) | 9.5 (Ton) |

| Double Wall Corrugated Pipe Production Line | ||||||||

| Model | SBW×1500 | SBW×1000 | SBW×500 | SBW×250 | SBW×160 | SBW×90 | ||

| Structure Form | Vertical | Vertical | Horizontal | Horizontal | Horizontal | Horizontal | ||

| Applicable Raw Materials | HDPE | HDPE | HDPE | HDPE | HDPE | HDPE | ||

| Pipe Diameter Range(mm) | ID(mm) | Φ400 | Φ250 | Φ160 | Φ90 | Φ75 | Φ40 | |

| OD(max) | Φ1500 | Φ1000 | Φ500 | Φ250 | Φ160 | Φ90 | ||

| Max. Extrusion Output (kg/h) | 1200 | 850 | 600 | 350 | 200 | 100 | ||

| Expansion Mode | Belling on-line, double-wall Socket Joint | Belling on-line, double-wall Socket Joint | Belling on-line, double-wall Socket Joint | |||||

| Forming Speed(m/min) | 0.25-2.5 | 0.25-2.5 | 0.4-4 | 0.5-5 | 0.6-6 | 0.8-8 | ||

| Axis Height(mm) | 1600 | 1600 | 1150 | 1100 | 1000 | 1000 | ||

| Number of Mold Blocks (pairs) | 42 | 42 | 40 | 48 | 57 | 48 | ||

| Total Installed Power(kw) | 820 | 660 | 385 | 240 | 150 | 95 | ||

Quality warranty:

1, We provide a one-year warranty on all products.

2, After sale service and parts interchange during warranty period free of charge.

3, Life time paid warranty available.

Your benefits with our machines:

All plastic extruder machinery components are fine tuned to work perfectly together, high quality level, latest machine design, engineered to meet the needs of customers in international markets, faster delivery times plus good service and spare parts.

Reviews

There are no reviews yet.