Plastic extrusion is not only a good business but also helpful for the environment. In the plastic extrusion process, people can recycle the waste, which is damaging to the environment, and produce a new product. Pipe, tubing, fence, window frames, plastic films, plastic boards and sheets, and wire insulation are all products of extrusion. Anyone may buy an extrusion machine and start a business that recycles plastic. Additionally, it is already in use by thousands of people worldwide. You can reuse the materials in the plastic extruding machine, which reduces raw materials and disposal costs.

A clear understanding of plastic pipe extruder machines.

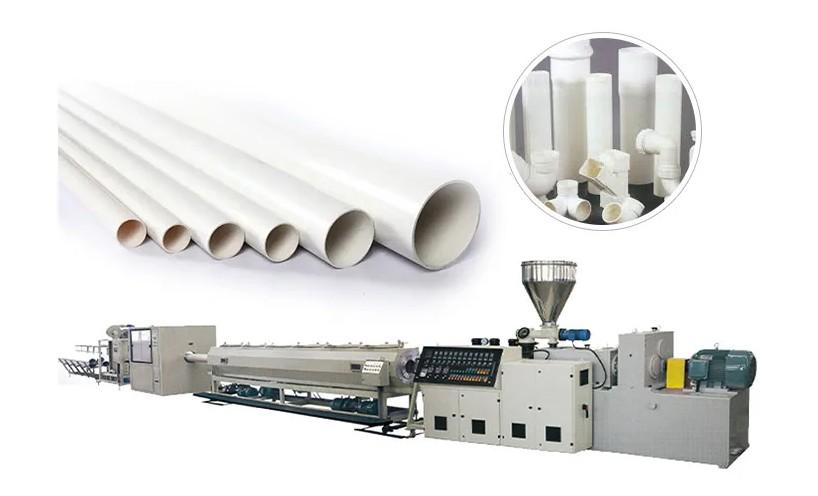

Extruding plastic produces a wide range of products, from conventional tubes used in industry to more ordinary household items. PVC pipe is a common component seen on a regular basis that is built using this method. Extrusion is a prominent production process in the plastics industry since it is inexpensive and simple to operate. Melting plastic material, pressing it into a die to form it into a continuous profile, and cutting it to length are the steps in the extrusion process for plastic pipe. It is a beneficial manufacturing option for pipes because of the low cost and high production rates. Also, it allows you a constant cross-section which is a helpful process to get a required product. We are going to cover some valuable points to get a better understanding of various plastic pipe-extruding machines.

Types of the plastic extruder.

The plastic extrusion procedure is normally cheaper than other plastic manufacturing methods. Whether you can use any type of plastic extruding machine all are worthwhile, cheaper, and flexible. The plastic extruding machines are divided by screw designs that indicate the difference in a machine’s length-to-diameter ratio, pitch, length of each zone, and helix angles of a screw. The three basic kinds of plastic extrusion machines are –

- Single Screw Extruder

- Twin or Multiple Screw Extruder

- Ram Extruder

A short description of the twin screw extruder.

A twin screw extruder is a device that has two co-rotating screws that mesh together and are placed in a closed barrel on splined shafts. A twin-screw extruder is more flexible because each screw speed can be adjusted independently of the other. These extruders are better at mixing ingredients. This machine has several benefits such as better control of operation parameters, higher process productivity, and increased business potential.

Advantages of twin-screw extrude

Comparatively, the twin-screw extruder is suited for powder processing and has good feeding characteristics. It performs better in terms of mixing, venting, reaction, and self-cleaning than a single-screw extruder. It has been widely used because of its strong feeding performance, mixing and plasticizing performance, exhaust performance, extrusion stability, and so on. Some crucial benefits of a twin screw extruder are given below.

- It has a high level of process flexibility.

- It offers higher business potential.

- Twin screw extruder is popular for saving electricity power.

- It reduces production costs.

- Because of the double screw, it has an excellent mixing capability.

- It provides higher process productivity.

- It has better control of process parameters.

Conclusion

Although ram extruders are also beneficial for plastic extrusion that don’t melt well with a screw, single and multiple-screw extruders are the most widely used. Extrusion screw design has evolved day by day, with improvements and concepts that help in constantly changing the procedure to fit the needs of unique applications.

You can also find china plastic pipe extruding machines that have other designs like barrier screws and mixing screws. You have to pick the screw design according to your business requirements.

Read also: How to select a standard single-wall plastic corrugated pipe extruder machine from the market?