Production description:

The methods for producing plastic sheets are commonly used for calendaring, mainly for the production of sheets such as PVC and PET, and the other for extrusion, for the production of sheets such as BOPS, EPS, PET, PP, HIPS.

Applications:

Plastic packaging sheets are mainly used in the production of disposable plastic cups, plates, bowls, plates, boxes and other thermoformed products, widely used in food, vegetable, fruit, beverage, dairy, industrial parts and other fields of packaging. With the increasing domestic demand, the use of packaged plastic thermoformed sheets is becoming more and more widespread, and the dosage is increasing year by year, and the prospects are promising. With the country’s emphasis on environmental protection, the “environmentally-friendly degradation sheet production line” adapted to production has been able to successfully supply various types of “degradable sheets” to the market.

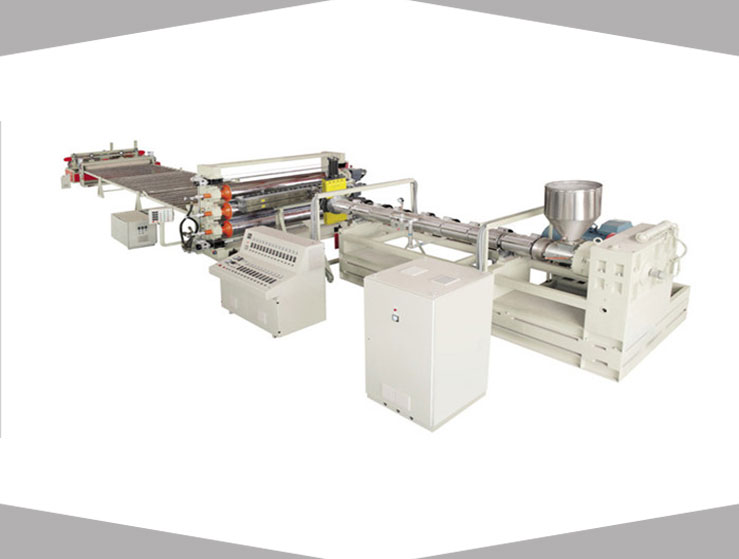

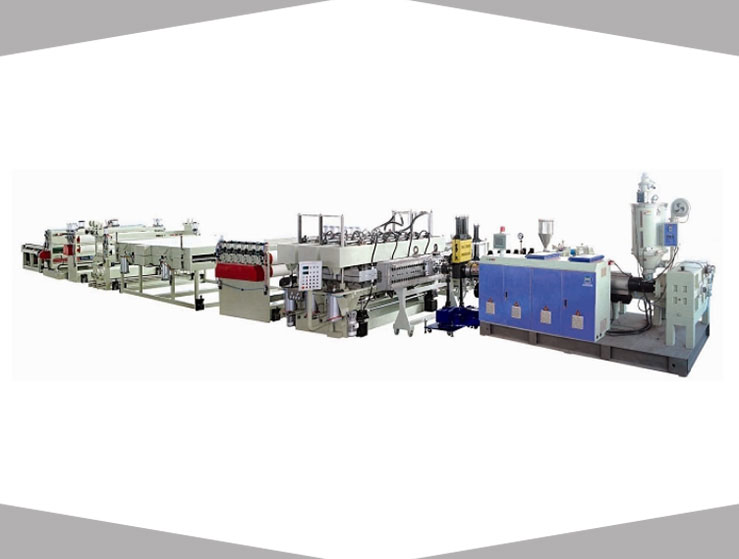

Machine parts:

- PET Non-crystallization extruding system :The newest screw thread unit, low power consumption, high output, is suitable foresheet extruding.

2.Three roller calendar: The high-precision three roller calendar forming system, with servo control, hydraulic compress structure, is suitable for the stable extrusion of sheet thickness at 0.15mm.

3.Precision die system:Can choose the self-regulation die to realize the change between extrusion mold and casting mold, is suitable for the sheet with different thickness.

4.Automatic rolling & cutting device:Easy to adjust, cutting straightness is high.Thickness:0.3-10mm,width:800-2000mm

Production Process:

plastic pellets→extruder: raw material melting and plasticizing →quick change filter → extrusion die forming → three-roll calender → cooling setting →trimming mechanism → traction → shearing device

Quality warranty:

1, We provide a one-year warranty on all products.

2, After sale service and parts interchange during warranty period free of charge.

3, Life time paid warranty available.

Your benefits with our machines:

All plastic extruder machinery components are fine tuned to work perfectly together, high quality level, latest machine design, engineered to meet the needs of customers in international markets, faster delivery times plus good service and spare parts.

Reviews

There are no reviews yet.