Introduction

In the world of cleaning and maintenance, innovation has found its way into even the simplest tools. Our journey today takes us into the realm of sweeping innovation as we unveil the power of our PET broom monofilament extruder machine. This remarkable technology is redefining broom production with a focus on durability, eco-friendliness, and unmatched efficiency.

The Evolution of Broom Filaments

Before diving into the intricacies of our PET broom monofilament extruder machine, it’s important to understand the evolution of broom filaments themselves. Broom technology has come a long way from traditional bristles. Polyethylene terephthalate (PET) has emerged as a game-changer in this field.

These filaments, crafted from PET, offer durability that outlasts traditional materials. PET is not only robust but also eco-friendly, aligning perfectly with the global push towards sustainability.

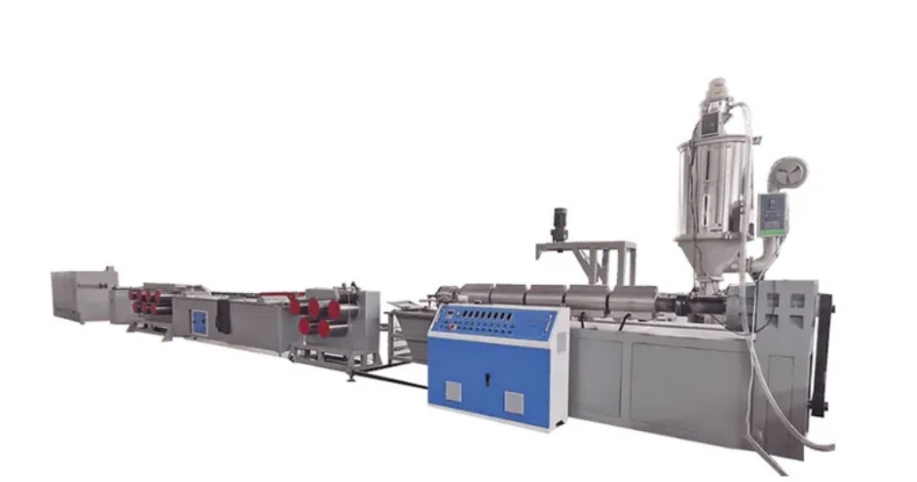

Cutting-Edge Technology: The Heart of Our Extruder Machine

At the core of our broom filament production lies our state-of-the-art extruder machine. This technological marvel is designed to set new industry standards in terms of durability, precision, and eco-friendliness.

Unmatched Durability

Durability is paramount when it comes to broom filaments. Our extruder machine ensures that each filament produced is of the highest quality, and capable of withstanding the toughest cleaning tasks. These filaments are built to last, providing brooms with exceptional longevity.

Precision in Production

Precision is a hallmark of our extruder machine. It guarantees that each filament is consistent in size and shape, contributing to the overall effectiveness of the broom. This precision ensures that every sweep is efficient and thorough.

Eco-Friendliness in Filaments

In a world increasingly concerned with environmental impact, our extruder machine plays a crucial role. By using PET, a recyclable material, we reduce the ecological footprint associated with broom production. We are proud to offer broom filaments that are not only durable but also eco-conscious.

Versatile Applications: Beyond Broom Production

While our PET broom filaments are ideal for broom production, their applications extend beyond cleaning tools.

Sustainable Solutions

Our commitment to sustainability extends to industries that prioritize eco-friendliness. By choosing our PET broom filaments, businesses can embrace sustainable practices, reduce waste, and demonstrate their dedication to environmental responsibility.

Custom Filament Solutions

Our extruder machine can be fine-tuned to produce filaments of varying sizes and properties. This versatility opens up opportunities for custom filament solutions in industries beyond cleaning.

Cost-Efficiency and Performance

In any industry, cost-efficiency and performance are essential considerations. Our PET broom filaments excel in both these aspects.

Cost-Efficiency Through Longevity

The durability of our filaments translates into cost savings for businesses and consumers alike. With brooms that last longer, fewer replacements are needed, reducing overall costs.

Maximum Performance, Minimum Effort

Our filaments are designed to make cleaning effortless. They offer superior performance, ensuring that every sweep is effective. This efficiency contributes to reduced cleaning time and labor costs.

Conclusion: Shaping the Future of Cleaning

In conclusion, our PET broom monofilament extruder machine is at the forefront of sweeping innovation. Its focus on durability, precision, and eco-friendliness makes it the preferred choice for broom production in various industries. Whether you’re in the cleaning sector, manufacturing, or seeking sustainable filament solutions, our extruder machine and PET broom filaments are shaping the future of cleaning.

So, embrace the technology that redefines broom production. Choose our PET broom filaments for durability, precision, and eco-friendliness that leave a lasting impact.