The world of plastic extrusion is both vast and intricate, encompassing a wide range of techniques and machinery designed to transform raw plastic materials into finished products. Among these, the plastic PVC, PP, and PC corrugated roof sheet extrusion line machine stands out as a pinnacle of technological advancement. This guide aims to demystify this complex machinery, providing insights into its operation, benefits, and how to master its use effectively.

Introduction to Plastic Extrusion

The basics of plastic extrusion involve heating, melting, and forming plastic into continuous shapes by pushing the molten material through a die. The evolution of extrusion technology has been significant, leading to the development of specialized machines like the corrugated roof sheet extrusion line, which caters to specific industry needs.

Understanding the Materials

PVC: Versatility and Durability – Polyvinyl Chloride (PVC) is a popular choice for construction materials due to its durability, resistance to environmental factors, and versatility in applications.

PP: Lightweight and High Performance – Polypropylene (PP) is known for its lightweight properties and high performance, making it ideal for creating more efficient and sustainable building materials.

PC: Clarity and Strength – Polycarbonate (PC) offers unmatched clarity and strength, perfect for applications requiring transparency and durability, such as skylights.

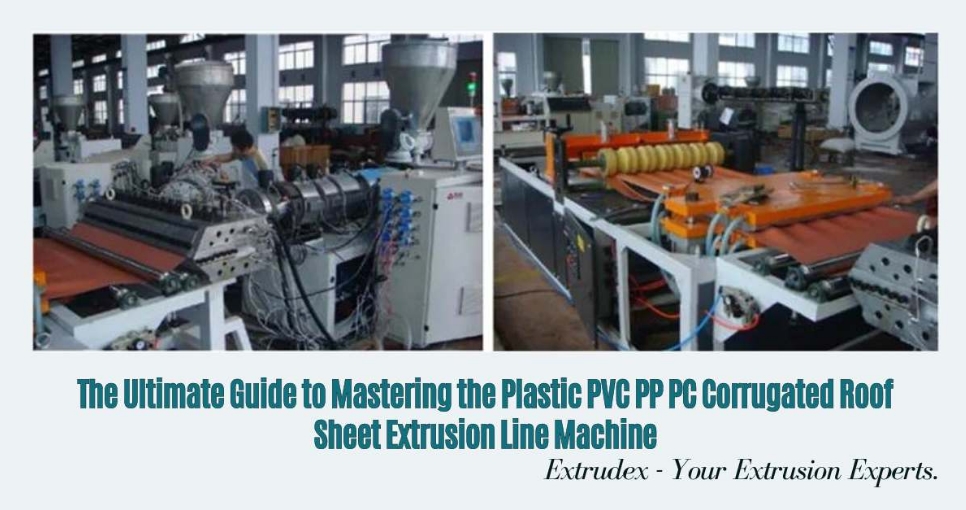

The Extrusion Line Machine

The heart of the process is the extrusion line machine, comprising key components such as the extruder, die head, cooling system, and cutters and pullers. Setting up and operating the machine requires precise knowledge and skill to ensure optimal performance and product quality.

Benefits of Using the Extrusion Line

Using a corrugated roof sheet extrusion line offers numerous benefits, including improved efficiency and productivity, versatility in production, and cost-effectiveness. These advantages make it a valuable asset in the manufacturing of roofing materials.

Maintenance and Safety Tips

Routine maintenance is crucial to prolonging the life of the machine and ensuring safe operation. Adhering to safety protocols can prevent accidents and ensure a healthy working environment.

Future Trends in Extrusion Technology

The field of extrusion technology is constantly evolving, with innovations aimed at improving efficiency, reducing environmental impact, and expanding the capabilities of extrusion machinery.

FAQ

1. What materials can be used in the corrugated roof sheet extrusion line machine?

The corrugated roof sheet extrusion line machine is versatile, capable of processing various materials including PVC (Polyvinyl Chloride), PP (Polypropylene), and PC (Polycarbonate). Each material offers unique properties, making them suitable for different applications in the roofing industry.

2. How does the extrusion line machine work?

The extrusion line machine operates by melting the plastic material, then forcing it through a die to form the corrugated shape. The process involves several steps, including feeding the raw materials into the extruder, melting and extruding the plastic, shaping it with a die, cooling the formed sheets, and finally cutting and stacking the finished products.

3. What are the key benefits of using this type of extrusion machine?

The key benefits include increased efficiency and productivity, as the machine can produce large volumes of roofing sheets rapidly. Additionally, it offers versatility in producing sheets of various sizes, thicknesses, and materials, and it’s cost-effective, reducing both production costs and waste.

4. What routine maintenance is required for the extrusion line machine?

Routine maintenance includes regular cleaning of the extruder and die, checking and replacing worn-out parts, lubricating moving parts, and ensuring the cooling system is functioning correctly. Regular inspections can prevent breakdowns and extend the machine’s lifespan.

5. How is the extrusion technology expected to evolve in the future?

Future trends in extrusion technology may include advancements in automation and control systems for improved precision and efficiency, the development of more sustainable and recyclable materials, and innovations in machine design to reduce energy consumption and increase output.

Conclusion

Mastering the plastic PVC, PP, and PC corrugated roof sheet extrusion line machine is an endeavor that promises significant rewards. By understanding the machinery, materials, and operational techniques, manufacturers can unlock new levels of productivity and innovation in the production of roofing materials.